People who often browse chip websites are no stranger to sop8, DIP8, LQFP and other words. What do sop8, DIP8, LQFP and other words mean? Very simple, this is actually the packaging of the voice chip and also the "outer packaging". Of course, there are some "round pimples" on the circuit board, which is also a form of packaging; So the question is, do different package sizes affect the quality of voice chips?

You know, the quality of the chip also depends on two aspects. On the one hand, the voice chip itself is in the process of design and production. The chip quality is determined by whether the chip design mainly has the design defects of the chip itself, and whether the design chip has corresponding protection errors other than the chip in the application process. The protection errors here are mainly power supply reverse connection protection, electrostatic protection, etc. Now the chips basically adopt CMOS technology internally. The main advantage of CMOS technology is low power consumption and relatively simple production, which can effectively reduce the cost. However, the disadvantage is also obvious, that is, CMOS is vulnerable to gate breakdown caused by external electrostatic interference due to the insulation between gate and source drain and high input impedance. Therefore, the corresponding protection circuit should be added to the grid. In general, our voice chip will add corresponding anti-static protection circuit. However, the chip generally carries out anti-static loss on the pins led out by the chip. If the chip does not add any electrostatic discharge, basically we touch the chip, it is likely to cause chip damage.

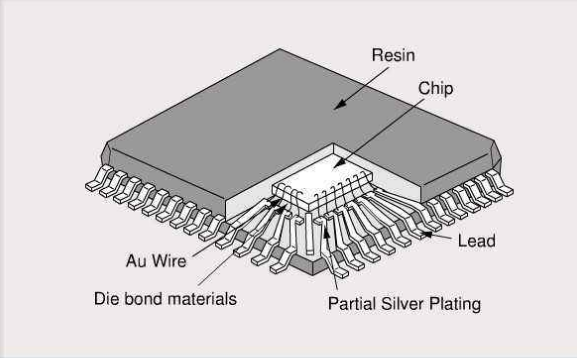

Nothing is absolute! I want to do computer assembly. Sometimes I've heard that the graphics card chip of a certain brand and model is unstable. In fact, it generally refers to the poor chip caused by problems in the later packaging process. Because the chip is a whole product, if you do not pay attention to anti-static loss in the packaging process, or the material used for packaging the chip is not very good. There will also be problems in the later stage of the chip. I believe that many electronic product manufacturers will also encounter such problems, that is, if there is no problem with the low-temperature welding of a chip, if the welding temperature is slightly higher, the chip will be relatively damaged. This problem is mainly caused by the different expansion coefficient of chip packaging materials. Due to the different influence of voice chip on the expansion coefficient of packaging materials at high or low temperature, coupled with the phenomenon of thermal expansion and cold contraction, the possibility of chip short circuit is not impossible.

News

News The working principle and classification of voice recognition chip

Sharing of Voice Module Selection Experience

Smart instrument voice chip, smart instrument voice IC

Popular voice MP3 module in the market

Transformer voice alarm scared the thief

The value of the air -conditioning fan added to the voice chip

Smoke alarm voice chip family safety assistant

Professional method of voice chip professional

Contact US

Contact US TEL:+86 18024055756

whatsAPP:+86 18024055756

E-mail:info@h-nec.com

Address:Room 401, Building 401, A5-01, No. 99 Science Avenue, Huangpu District, Guangzhou City, Guangdong Province from China