What is encapsulation? What are the packaging of voice chip? The packaging form (package) of voice IC refers to that IC is a package with different shapes formed by putting a large number of integrated circuits formed by microelectronic components (transistors, resistors, capacitors, etc.) on a plastic base to make a chip in different types of frames (L / F) and plastic packaging materials (EMC). So how much do you know about the voice IC packaging form? Get to know Xiaobian.

By packaging material:

Metal packaging: used for military or aerospace technology, no commercial products

Ceramic packaging: ceramic packaging should take precedence over metal packaging. At the same time, it is also used in military products, and a small part is used in the commercial market

Plastic packaging: used for consumer electronics. Low cost, simple process and high reliability

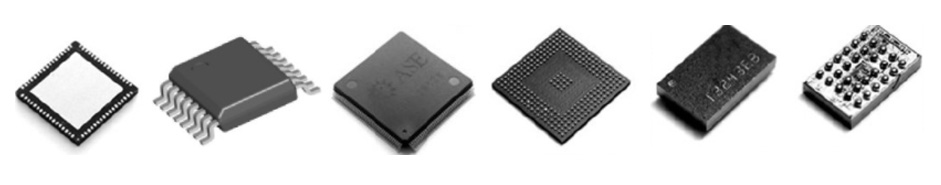

Common outline packages of voice IC include:

SOP (small outline package, double-sided surface mount package)

SOP packaging is a form of component packaging. Common packaging materials include plastic, ceramic, glass, metal, etc. now plastic packaging is basically used, It has a wide range of applications, mainly used in various integrated circuits. Then there are TSOP (thin small outline package), VSOP (very small outline package), SSOP (reduced SOP), tssop (thin reduced SOP), MSOP (micro outline package), qsop (quarter size outline package), qvsop (quarter volume ultra small outline package), etc. (most commonly used in voice IC)

QFP (Quad pin flatpack)

This package is a square flat package, which is generally square and has pins on all four sides. The distance between the pins of the CPU chip realized by this package is very small and the pins are very thin. This package is generally used for large-scale or very large-scale integrated circuits, and the number of pins is generally more than 100. Because of its small package size and reduced parasitic parameters, it is suitable for high-frequency applications. Such packages include cqfp (ceramic quad flatpack), PQFP (Plastic Quad flatpack), ssqfp (self welded Quad flatpack), TQFP (thin Quad flatpack) and sqfp (reduced Quad flatpack)

SOT (small form factor transistor)

SOT is a kind of chip package. Usually, the chip package of devices with pins of 5 or less (3-pin, 4-pin) has a small size. Many transistors use this kind of package.

SOIC (small outline IC package)

SOIC is a small integrated circuit package with no more than 28 external leads. It generally has two packaging forms: wide body and narrow body. Compared with the same dip package, SOIC reduces the space by about 30-50% and the thickness by about 70%.

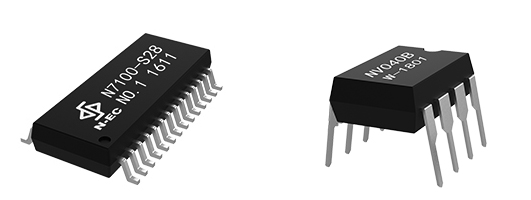

Dip (dual in-line package)

Dip packaging is one of the simplest packaging methods. Refers to the integrated circuit chip packaged in the form of dual in-line. Most small and medium-sized integrated circuits adopt this packaging form, and the number of pins generally does not exceed 100. The dip encapsulated voice chip has two rows of pins, which need to be inserted into the chip socket with dip structure. (most commonly used in voice IC)

What is the difference between SOP and dip encapsulation in voice IC?

Functionally

If only from the functional point of view, there is no difference in the function of the same model of voice chip. For MCU development, it is recommended that you use dip encapsulated voice chip, because it is easier to do experiments. For and formal production, it depends on the situation Because the pins of SOP encapsulated voice chip are very short, the parasitic inductance and capacitance are generally smaller than that of dip encapsulated voice IC.

On price

If they are different, it can only be the difference in price, Generally speaking, the price of voice chips encapsulated in SOP is cheaper than that encapsulated in dip under the same conditions (because under the same material cost, the voice chips encapsulated in SOP are not soldered as well as those encapsulated in dip. Generally, reflow soldering is required for production. Manual welding is possible only when experiments are carried out, and dip packaging welding is easier.) Of course, the price is also related to factors such as shipment volume. The specific need is to communicate with the voice chip manufacturer. Of course, in the same case, the use of MCU has no impact

News

News What are the models of voice chips on the market now?

Precautions for the location of the point of the sound and light voice alarm

Nine Chip electronic voice chip NR9600 Features

Guangzhou Jiuxin Electronic NVB series voice chip introduction?

Voice chip, recording chip selection

Contact US

Contact US TEL:+86 18024055756

whatsAPP:+86 18024055756

E-mail:info@h-nec.com

Address:Room 401, Building 401, A5-01, No. 99 Science Avenue, Huangpu District, Guangzhou City, Guangdong Province from China